Share

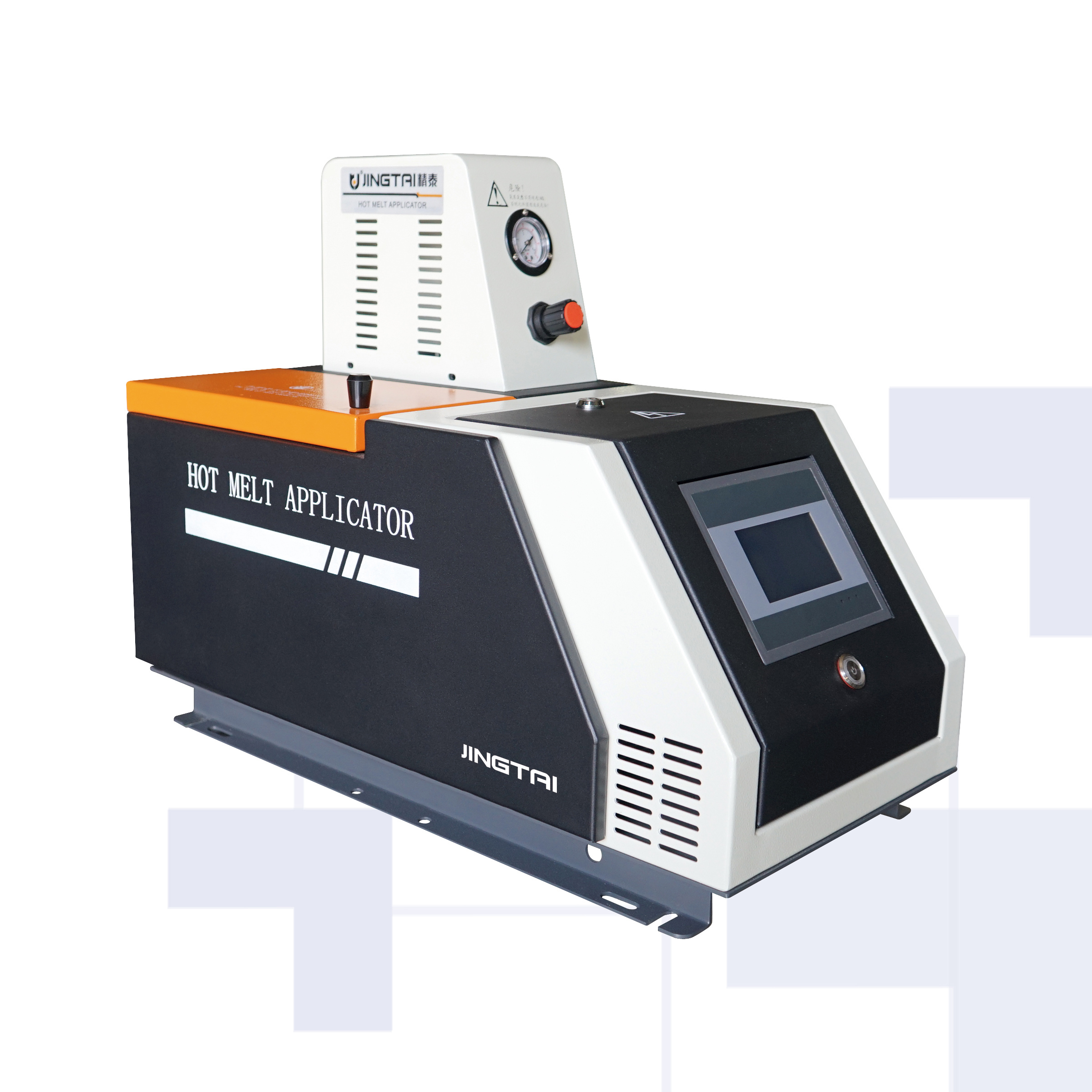

PUR05

Classification

Product Details

The PUR hot melt glue machine is a special type of hot melt glue machine equipment, as PUR hot melt glue cannot come into contact with air; the hot melt glue is sealed within the machine. When the PUR hot melt glue machine is in operation, it does not require drying or auxiliary drying equipment because the hot melt glue is environmentally friendly and pollution-free, thus not causing environmental pollution. Additionally, the PUR hot melt glue machine can be paired with various automated production lines. In woodworking machinery, it is commonly used in conjunction with coating machines. Thirdly, the PUR hot melt glue machine can perform low-temperature spraying operations, which saves energy consumption to some extent and is suitable for bonding heat-sensitive materials. Fourthly, the PUR hot melt glue machine is easy to operate but has a long service life and excellent heat and cold resistance characteristics. It is mainly used for bonding PVC plastic boxes, PET transparent boxes, electronic products, and other paper boxes.

The product is widely used in automotive front and rear lights, windshields, door manufacturing and interiors, air filters, bottle caps, shoe material bonding, PVC/PET transparent box packaging, woodworking machinery, non-woven fabric material composites and other breathable composite products, hot melt adhesive spraying composite equipment, rolling adhesive composite equipment matching etc.

Machine Features:

1. Composed of three parts: main unit, throat pipe (insulation pipe), manual/automatic glue gun. It has functions such as temperature upper and lower limit alarms, glue level detection alarms and inverter abnormal alarms.

2. Progressive heating melting: The heating plate is located above the adhesive; when the heating plate heats up, only the top layer of adhesive contacts with it to reach its melting point while the lower part of the adhesive barrel remains unheated to avoid aging or deterioration from prolonged heating.

3. During melting process adhesive is isolated from air: There are high-temperature resistant sealing rings between the heating plate and inner wall of the adhesive barrel to ensure that melted liquid adhesive does not come into contact with air to meet PUR usage conditions.

4. Teflon protective layer: The outer surface of the heating plate is coated with Teflon which makes it easy to clean off any residual adhesive while effectively preventing carbonization of the adhesive ensuring optimal quality and preventing clogging in the adhesive delivery system.

5. Precision gear pump, pneumatic return valve, inverter and motor are all supplied by high-quality suppliers or processed using high-precision machining center equipment ensuring top-notch quality; stepless variable frequency speed regulation combined with self-feedback adjustment of pneumatic return valve allows precise control over output of adhesive.

6. The main motor operates humanely; when the heating plate has not reached operating temperature yet, the main motor cannot operate to avoid operational errors by staff.

7. Human-machine interface operation can provide options for 7-inch or 10-inch screens.

8. The outer layer of sealing ring on heating plate uses Teflon coating suitable for high-temperature PUR hot melt glue machines.

9. The heating rods on the heating plate can be replaced individually reducing after-sales costs.

Product Specifications

| Item | Unit | Model |

| PUR05 | ||

| Heating tank capacity | (L) | (5) |

Inner diameter of barrel | (MM) | (280/286) |

| (Maximum melting rate) | L/Hour | (≥20) |

| (Maximum operating temperature) | (℃) | (180) |

| (Air pressure range) | Kg/cm2 | / |

| (Size) | (mm) | (1090*540*1740) |

| (Weight) | (Kg) | (150) |

| (Maximum usable viscosity) | (CPS) | (1000-50000) |

| (Number of insulation pipes and spray guns) | (SET) | (1-2) |

| (Pump type) | / | (Gear pump) |

| (Total power) | (W) | (4400) |

PUR05

Classification

Product Inquiry

Note: Please leave your mobile phone and E-mail, and our professionals will contact you as soon as possible!

Contact Information

Address: 157 Wanhong Road, Shuangyang Street, Luojiang District, Quanzhou City, Fujian Province

Mobile website