Share

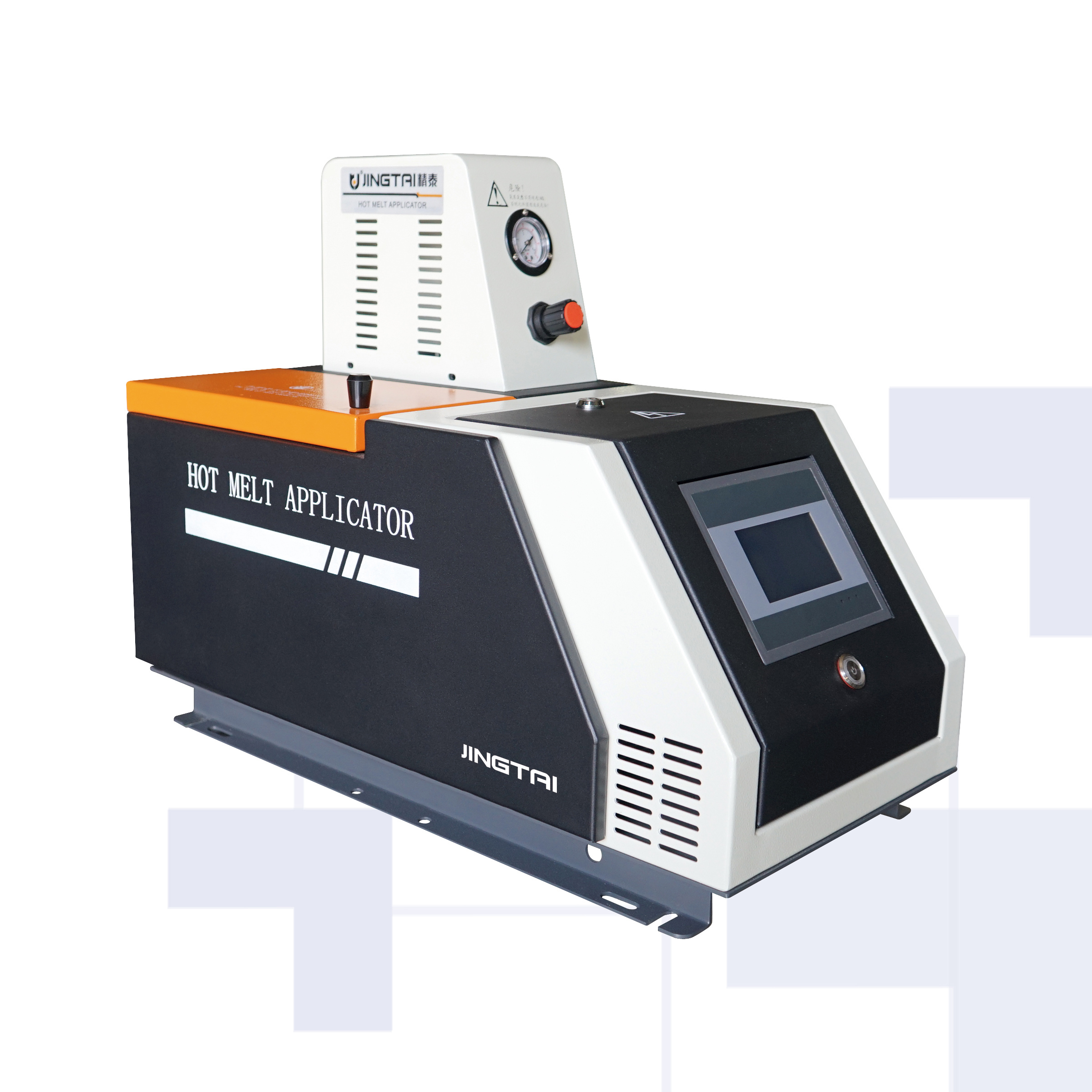

P10S

Classification

Product Details

This series of glue machines, which use a pneumatic pump to supply glue, is commonly referred to as a 'piston pump hot melt glue machine'. Its working principle involves using air pressure to drive the piston pump for glue delivery. Therefore, the stability of this hot melt glue machine is largely controlled by stable air pressure. It requires correct air pressure control; fluctuations in air pressure will affect the stability of glue spraying. The equipment from Jingtai uses imported piston pump technology with fast response and sensitivity, effectively ensuring the stability of the glue output during the up and down stroke of the air pump. It is widely used in various industries, providing effective glue spraying for bonding in different sectors. It is an energy-saving, efficient, and environmentally friendly glue machine, widely used in fields such as cardboard packaging, cosmetic gluing, and electronic dispensing.

Glue output method:

1. Optional strip-shaped, dot-shaped, or spray.

2. Optional automatic spraying, semi-automatic spraying or handheld spraying.

Application industries:Packaging, filters, gift boxes, cosmetic caps and automation machinery accessories.

1. Used for high-end book-type boxes, mooncake boxes, food boxes, wine gift boxes and other gift boxes and cardboard box sealing spray gluing.

2. Various cosmetic packaging materials such as aluminum caps for cosmetics, cream caps, spray heads, pump heads, essential oil caps and gift boxes are sprayed with glue.

3. Express bags, bubble bags, envelope bags, document bags, tote bags and other paper bag sealing spray gluing processes replace double-sided tape functions.

4. Automotive industry (interior sealing, car light manufacturing, windshield assembly; bodywork; foot pedals; seats; ceiling doors and windows sealing etc.).

5. Home appliance industry such as refrigerator sealing and filling; mattress gluing; etc., product assembly (home appliances and furniture bonding).

Features:

1. Equipped with a hose for automatic spray control used on production lines; adhesive height and angle can be adjusted;

2. Equipped with a hose and handheld spray gun for large area mobility;

3. Optional configuration of 1-4 sets of pipe guns to save procurement costs;

4. High-strength integrated molding melting tank with heated diverters that increase heating area to improve melting speed; melting tank uses anti-stick layer technology from Teflon.

(Dragon) smooth inner wall structure effectively prevents adhesive carbonization.

5. Piston pump processing precision (using foreign processing technology), effectively ensuring stable output during the up-and-down stroke of the air pump.

Product specifications

| Project | Unit | Model |

| P10S | ||

| Heating tank capacity | L | 10 |

| Maximum melt adhesive speed | L/Hour | ≥5 |

| Maximum operating temperature | ℃ | 200 |

| Pressure range | Kg/cm2 | 4-6 |

| Size | mm | 805*355*550 |

| Weight | Kg | 66 |

| Maximum viscosity for use | CPS | 1000-12000 |

| Number of insulation pipes and spray guns | SET | 1-4 |

| Pump type | / | Air pump (piston pump) |

| Total power | W | 4400 |

P10S

Classification

Product Inquiry

Note: Please leave your mobile phone and E-mail, and our professionals will contact you as soon as possible!

Contact Information

Address: 157 Wanhong Road, Shuangyang Street, Luojiang District, Quanzhou City, Fujian Province

Mobile website