Share

6320

Classification

Product Details

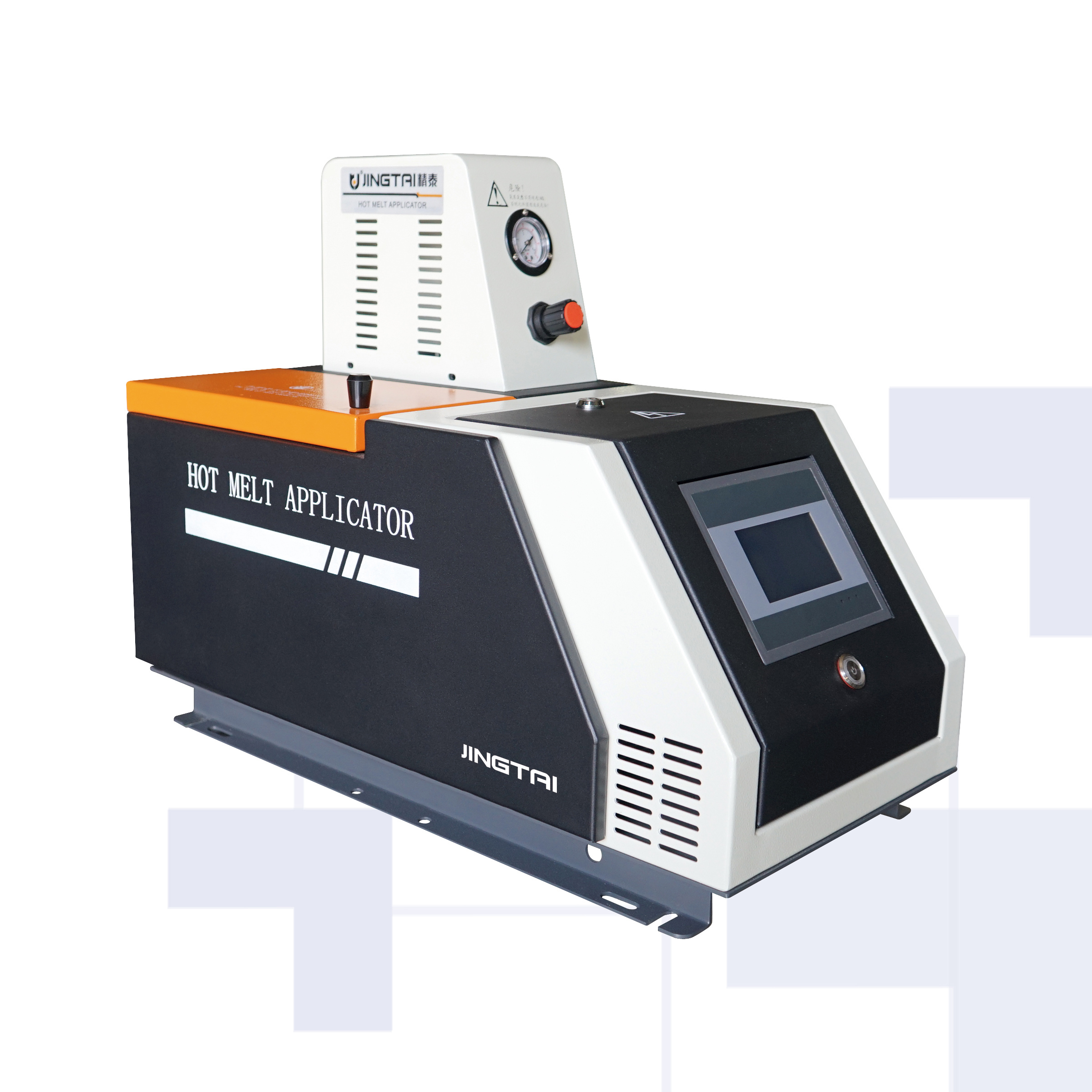

This series of equipment mainly works on the principle of a motor driving a gear pump to dispense glue. It is suitable for high-viscosity hot melt adhesives and is a large-capacity glue machine that can automatically spray, work efficiently for long periods, has a long service life, and is easy to maintain and repair. It can meet the needs of different industries to achieve supply-demand balance, with glue machines available in 10-120Kg options, and special models can be customized.

Application Industries:

★ Packaging Industry (carton packaging, manual sealing, tobacco and alcohol box packaging, food box packaging, sports equipment packaging, heaven-and-earth cover paper boxes, honeycomb cardboard)

★ Air filter elements, non-woven fabric composites, footwear industry, printing, garment manufacturing, coating composite industry

★ Product assembly (home appliances, furniture bonding, wire and cable assembly, refrigerator sealing and caulking)

★ Automotive Industry (manufacturing of headlights, windshield assembly, bodywork, interior sealing for roof windows and doors)

★ Household mattress daily necessities (mattress foam, mattress springs, sofa cushions)

Features

★ The frame-style body structure and openable control cabinet door design make installation and maintenance simple and quick; user-friendly bottom wheel device allows for flexible movement with a locking function that enhances safety; the operation panel is designed for ease of use.

★ Capable of supporting automatic glue application on production lines with robotic arms for automatic dispensing; different glue application methods can be provided based on various product processes.

★ High-strength integrated melting glue tank with blade-shaped heating diverters increases heat transfer area to improve melting speed; the melting tank has a Teflon anti-stick layer to prevent adhesive buildup; the inner wall has a smooth structure without sharp edges to effectively prevent adhesive carbonization and ensure optimal adhesive quality; precision filtering devices remove impurities to prevent nozzle clogging.

★ Equipped with variable frequency speed control to effectively manage the amount of glue dispensed.

★ Gear pump processing precision (using foreign processing technology) effectively ensures stability in glue output.

★ Optional configuration of 2-4 sets of spray stations saves procurement costs.

Product Specifications

| Item | Unit | Model | Model | Model | Model |

| 6320 | 6340 | 6360 | 63120 | ||

| Heating tank capacity | L | 20 | 40 | 60 | 120 |

| Maximum melt adhesive speed | L/Hour | ≥20 | ≥40 | ≥60 | ≥120 |

| Maximum operating temperature | ℃ | 200 | 200 | 200 | 200 |

| Pressure range | Kg/cm2 | 4-6 | 4-6 | 4-6 | 4-6 |

| Size | mm | 1070*520*1070 | 930*520*1240 | 1000*675*1400 | 1200*800*1400 |

| Weight | Kg | 160 | 190 | 240 | 400 |

| Maximum viscosity for use | CPS | 1000-50000 | 1000-50000 | 1000-50000 | 1000-50000 |

| Number of insulation pipes and spray guns | SET | 1-4 | 1-4 | 1-4 | 1-4 |

| Pump type | / | Gear pump | Gear pump | Gear pump | Gear pump |

| Total power | W | 7900 | 11400 | 13000 | 20000 |

6320

Classification

Product Inquiry

Note: Please leave your mobile phone and E-mail, and our professionals will contact you as soon as possible!

Contact Information

Address: 157 Wanhong Road, Shuangyang Street, Luojiang District, Quanzhou City, Fujian Province

Mobile website